Control & Relay Panels

Exact. Exceptional. Every time.

Control & Relay Panels

Exact. Exceptional. Every time.

The most precise path from concept to completion.

At Systems Control, our control and relay panels are custom-designed and built to meet your exact specifications.

Our design teams use 3D engineering software to ensure each step of the manufacturing process meets your exacting standards and specifications. From fabrication to functional testing, our engineering teams will work with your technical staff to give you what our customers have come to expect—extraordinary customer service.

Systems Control is the largest turnkey control panel designer, manufacturer and integrator in North America. There’s no job too big or too small for us.

Control & Relay Panel products:

Modular Rack Front Panels

Can be customized for height, width, and depth to customer requirements. Rack fronts can be customized to customer’s component/device needs.

Solid Front Panels

Can be customized for height, width, and depth to customer requirements, including matching color for existing substations.

Duplex Panels

Duplex panels can be designed to customer’s specifications, including precise requirements for wire troughs, panel interconnect wiring, and terminal block locations.

Rack Panels & Plates

Highly customizable including Unistrut panels.

We are pushing towards more turnkey solutions because you can do more extensive testing multiple times beforehand in a controlled factory environment. This means we don’t have to take long outages to test it out on-site.

— Project Manager, National Utility

Turnkey Approach

No provider matches our range of end-to-end capabilities:

Engineering

We have Professional Engineer (PE) certified engineers prepared to handle your critical design projects. Your dedicated project manager and design team will work with you, from inception to installation.

Manufacturing

From raw steel to complete turnkey solutions – every cut, bend, weld, paint finish, crimp, and wire assembly is the subject of our constant attention to detail.

Integration

There are thousands of components and connections in an enclosure. You need them to fit together and work seamlessly to provide the solutions you need. Use the company that does it all under one roof and takes testing all the way to pre-commissioning in-factory.

Testing

We perform full functional testing of our panels and enclosures. Our objective is to catch every issue—whether they are the result of customer drawings, component suppliers, or customer outsourced engineering companies.

Installation

Our enclosures, control panels, and turnkey solutions are delivered in critical applications across the country. Using Systems Control’s patented METS enclosure delivery system we are able to deliver enclosures where others can’t. Our central location means we can deliver product for installation, anywhere in the continental US within 3-5 days of completion.

Quality isn’t a box to check, it’s a commitment

From start to finish, a relentless pursuit of perfection.

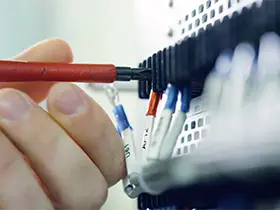

Wiring:

Cut to length, labeled and placed into individual harnesses with exacting precision – that’s Systems Control. Every connection we make is functional and durable with outstanding craftsmanship.

Crimping:

We take the extra step of testing every crimper, every shift, with every employee.

testing:

Panel wiring, building wiring and integration – all tested with our North American leading Utility Benchmark standard.

Certification:

ISO 9001:2015 certified through Amtivo.

Safety Always

Safety Always is paramount to our business and our number one Core Value. It’s something we all own: every employee, every minute, every day.

From our facility to our customers’ job sites, we know the more time we spend ensuring every connection, every wire, every panel, and every enclosure is built to the highest standard, the safer we keep every worker.

It’s good business, and it’s simply the right thing to do.